Workplace Shadow Boards and Plant Productivity

Posted by ASG Services on Oct 9th 2023

Shadow boards are a simple yet effective way to organize and store your workplace tools. They are one of the most cost-efficient ways to keep implements in check, making them an ideal choice for any workplace. With shadow boards, you can ensure accuracy, safety, and accountability within your company.

Companies introducing a lean system typically start with a 5S implementation. It is often best as 5S provides a swift and positive impact as well as a review of organizational necessities. Many firms stall at this point, feeling they have successfully deployed the lean system, forgetting that this is just the beginning.

Companies introducing a lean system typically start with a 5S implementation. It is often best as 5S provides a swift and positive impact as well as a review of organizational necessities. Many firms stall at this point, feeling they have successfully deployed the lean system, forgetting that this is just the beginning.

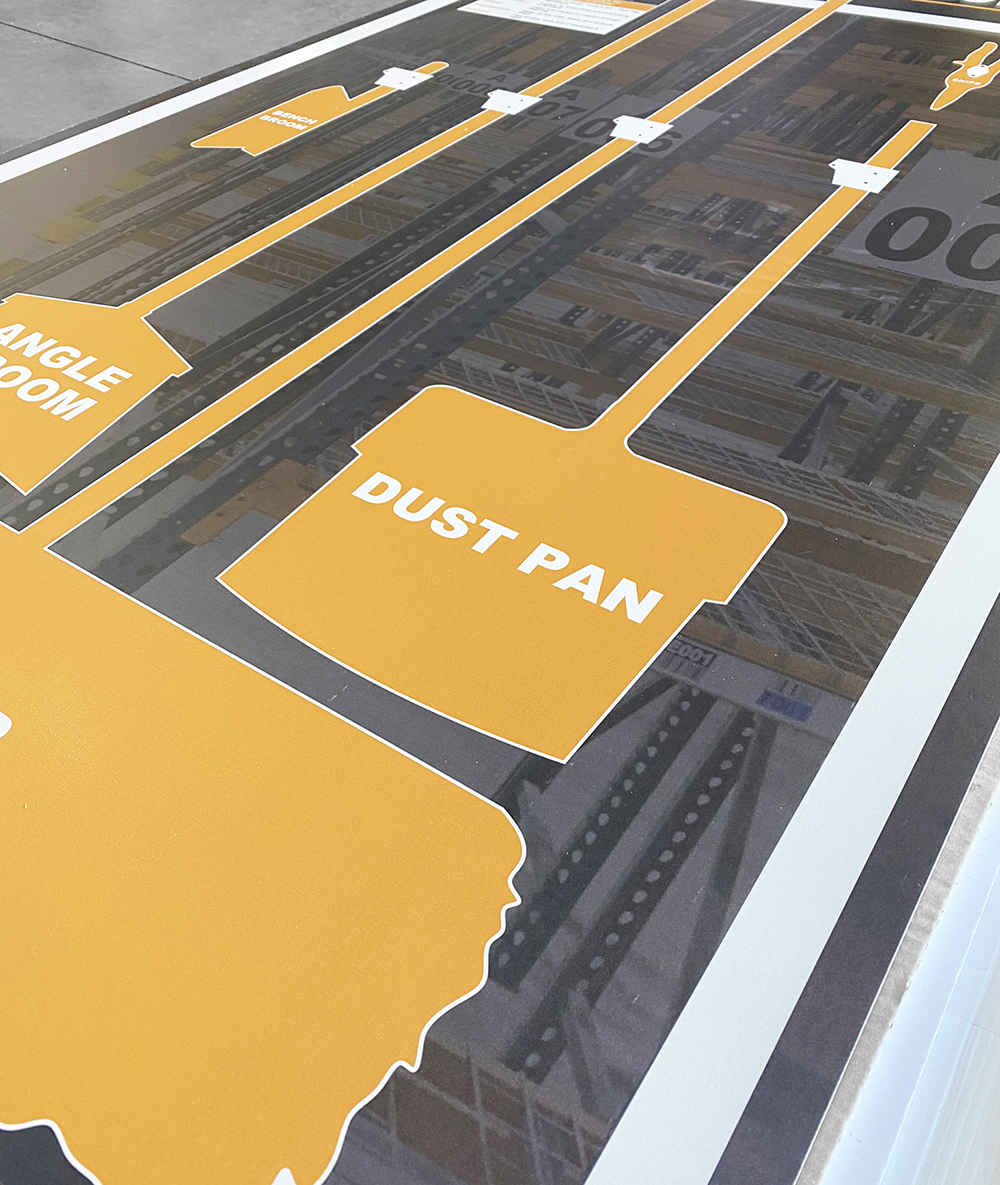

An example of where a 5S initiative can progress with a visually impactful sortation, are shadow boards. Shadow boards provide a means of presenting tools or cleaning implements, so they can be quickly and easily selected when required. Once removed, a depiction and often a description of the item remains, so each can be accounted for.

Shadow boards are generally located in work areas, central to activities and at workstations where specific tooling is required in manufacturing and assembly processes. They help create a better work environment by making sure that tools and implements are accurately placed after use. This helps eliminate the possibility of workplace hazards due to misplaced items and allows employees to easily locate what they need when it’s time for them to get back to work.

ASG Services, the warehouse identification and marking specialist in Buford, GA, design customer shadow boards for this very reason. Not all facilities are the same, each storing unique goods, therefore, a cleaning station shadow board in a fashion retailers distribution center, will need considerably different implements to that of a beverage warehouse.

Taking customer branding, tooling needs and size constraints, ASG Services can create the boards, with hardware and implements pre-assembled, and shipped to site ready for use, and for the customers or ASG’s installation teams to mount.

5 Benefits of Properly Designed Shadow Boards

Efficiency and Productivity: Properly designed shadow boards allow for quick and easy identification and access to necessary tools, saving time, and improving productivity. No more wasted time searching for the right implement; everything is visible and readily available.

Efficiency and Productivity: Properly designed shadow boards allow for quick and easy identification and access to necessary tools, saving time, and improving productivity. No more wasted time searching for the right implement; everything is visible and readily available.- Safety: Shadow boards reduce the risk of accidents and injuries in the workplace. By providing a specific spot for each tool, they eliminate potential hazards caused by misplaced implements.

- Organization and Cleanliness: A well-ordered work environment is conducive to efficiency and effectiveness. With shadow boards, tools and implements are kept neat, which also contributes to maintaining cleanliness in the workplace.

- Accountability and Responsibility: Shadow boards can also promote personal accountability and responsibility among employees. It becomes immediately clear when a tool is missing or not returned to its proper place.

- Preservation of Tools: Shadow boards help to preserve the condition of the tools. By providing a secure place for each tool, they prevent needless wear and tear that could occur from improper storage.

Why 5S Works in Logistics and Distribution

The 5S methodology, originating from Japan, can significantly enhance any workplace environment, specifically those in manufacturing, assembly, warehousing, and distribution centers. This approach comprises five steps, Sort, Set in Order, Shine, Standardize, and Sustain, that aim to improve efficiency and safety.

Sorting, the first step, involves discarding unnecessary items and streamlining tools. This prevents clutter and paves the way for improved workflows. With set in order, every tool and implement has a designated place, often marked with shadow boards, contributing to faster access and better organization. Shine emphasizes regular cleaning and maintenance; a neat and clean workplace not only minimizes the risk of accidents but also boosts employee morale. Standardization ensures uniformity across all processes, enabling easier training of new staff and consistent output quality. Lastly, sustain involves creating a culture of continuous improvement, encouraging everyone to maintain and improve new, efficient systems.

The components of 5S can be related to any company. In logistics, where time and space optimization are critical to the success of an operation, the impact and return on investment in achieving a 5S system is clear to see.

The Interactive Sign that Is Not Digital

Shadow boards are an extension of an effective signage plan, which is integral to implementing the 5S methodology successfully. Signs and labels, like shadow boards, act as visual controls that can significantly impact each stage of the 5S process.

During the sorting phase, clear, well-placed labels help identify excess tools and unnecessary items, contributing to a more organized workspace. For ‘set in order’, labels and signs are used to designate specific areas for each tool and implement, expediting their retrieval and return, hence reducing wasted time. During the ‘shine’ phase, signs indicating cleaning schedules and responsibilities ensure regular maintenance and cleanliness. In the standardize phase, signage helps maintain consistent practices across a workplace by providing clear, uniform instructions that are easily understood by all employees. Finally, in the sustain phase, signage supports continued adherence to 5S practices and fosters a culture of continuous improvement.

Therefore, a comprehensive signage plan is not just an add-on, but a critical component of a successful 5S implementation. ASG Services custom sign services have provided 5S sign products for small- and large-scale rollouts, in conjunction with their barcoded warehouse label, sign, and floor marking solutions. Integrating branding, messages, images, and safety guidance is a unique service on the scale needed for industrial facilities.

Buy warehouse labels and warehouse signs here.

Shadow Boards and Floor Marking are Family!

The relationship between shadow boards and floor marking in warehouses and manufacturing plants cannot be overstated. Floor markings help to identify where each machine, device, tool, and pallet should sit as well as where people should walk, while shadow boards keep everything neatly organized and in place, reducing accidents, promoting safety, and increasing productivity.

5 Benefits of Floor Marking for 5S Implementations:

- Quick and easy organization: Floor marking can help to quickly define work zones, segregate materials, highlight dangerous aisles or pathways and improve the overall safety of the facility.

- Improved workflow: By streamlining processes with floor markings, you can reduce unnecessary steps in manufacturing or logistical operations while increasing efficiency.

- Enhanced communication: Brightly colored floor markings can easily indicate the status of a product or work zone, making it easier for teams to understand what is required.

- Improved safety: By clearly indicating where people should walk, stand, and operate machines, floor marking can help to reduce slip hazards and other types of health and safety issues.

- Long-term sustainability: Floor markings are durable and can last for years, making them an excellent long-term solution for safety and organization.

Ultimately, workplace shadow boards and floor marking go hand in hand when it comes to streamlining operational processes. ASG Services work closely with customers to help them achieve their floor marking needs, by providing some of the most durable solutions available, alongside the most cost effective. Combining multiple methods helps achieve the required markings, within budget constraints, while being as durable as possible.

Buy floor striping tape and floor signs.

In Summary…

Shadow boards play their part in significantly enhancing plant productivity, within a 5S system, by providing a clear, visual indication of tool placement, supporting rapid identification and retrieval. This leads to less wasted time searching for implements and enabling faster task completion.

Moreover, shadow boards contribute to the maintenance of a well-organized and clean workspace, which is fundamental for reducing potential safety hazards and inefficiencies such as misplaced or lost tools. They also support the standardization of procedures by ensuring that every tool has a designated place and fostering consistency in work routines.

Furthermore, the integration of shadow boards into a comprehensive signage plan bolsters the implementation of the 5S methodology, a proven approach to improving productivity by promoting an orderly, efficient, and safe work environment.

Visit our project website and read more about our specialist services and custom shadow boards.

Download the Workplace Shadow Boards and Plant Productivity paper for later, or pass it to a colleague: